| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | BLM-TR-1 |

| Price : | exw usd 25/pc |

| Payment Terms : | Western Union, L/C, T/T |

| Supply Ability : | 3000 pc/pcs per Month |

| Delivery Time : | 25-30 days subject to the clients' requirement and quantity |

| Model Number : | BLM-R |

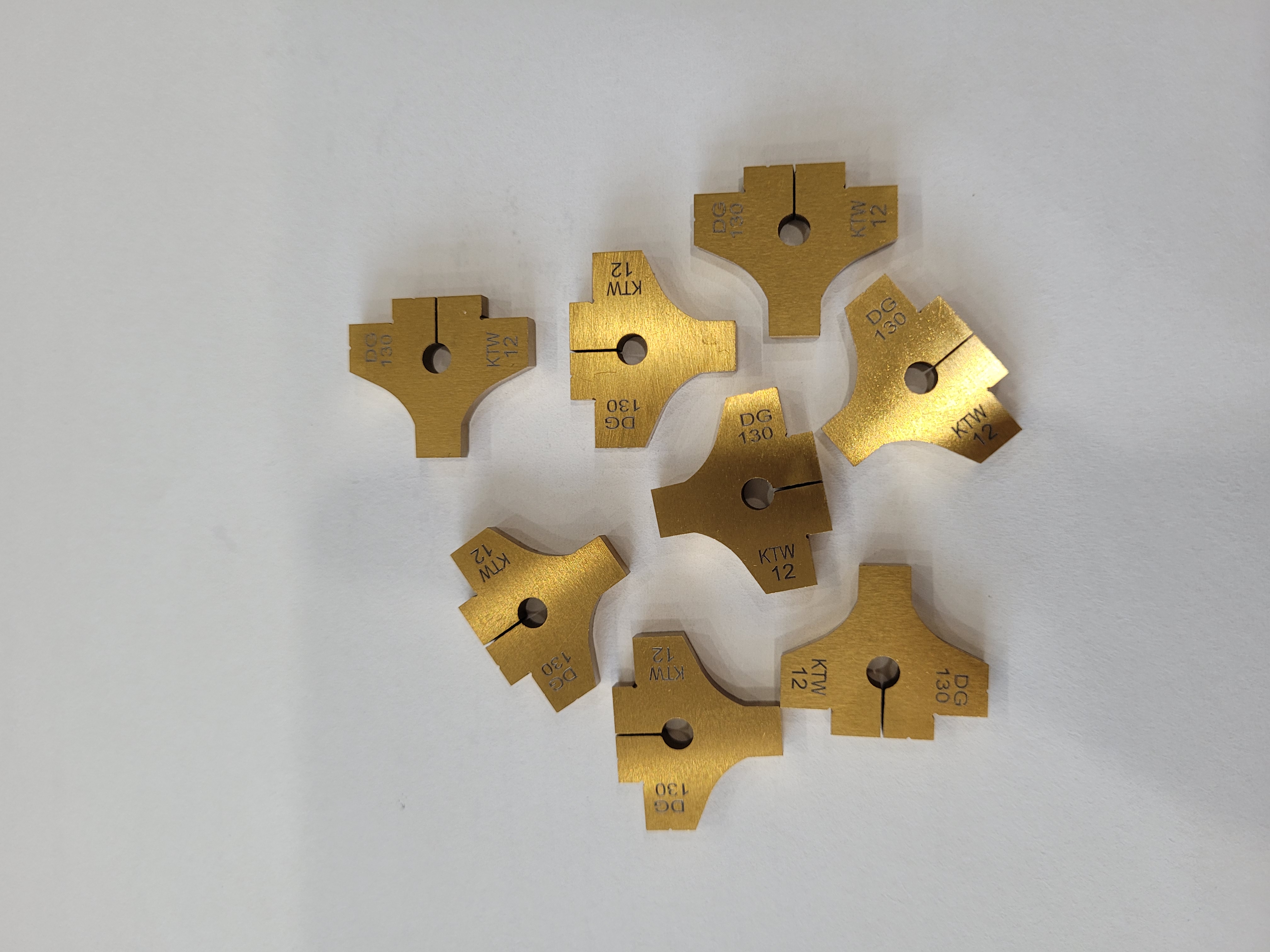

Spot Welding Machine Parts Cutter KTW-12 For Tip Dresser

1 . Description

Dianjin provide various types of tip dresser.Include pneumatic tip dresser(air tip dresser),manual tip dresser,ratchet handheld tip dresser,drill tip dresser etc.Our tip dresser consists of tip dresser tool,cutter blade,cutter holder. They are popular used to cut Φ8-Φ25 electrode tips.We supply all kinds of standard tip dresser cutter blade.Also offer customized tip dresser cutter according to your drawing.Compressed air provides power source for the pneumatic tip dresser.It’s rotating speed is 1300RPM-1500RPM.If you need spot welder tip dresser,electrode tip dresser,please contact our sales.

Proper tip dressing helps maintain weld consistency and quality in spot welding applications while also saving time and money. Robotic tip dressers with dual-sided sharpeners/shapers for resistance welding electrodes — are generally mounted on stationary stands for robotic weld gun arms and on retractable swing arms for pedestal welding units. Repeated exposure to high temperature and pressure alters copper electrode tip geometry over a number of welds. Tip dressing resets the electrode shape to help your company meet the precise specifications of your customers.

Electrode maintenance is critical to weld quality. Specify an electrode shape — and help it stay that way — to maintain the consistency of each weld. Even with proper weld parameters and water cooling, copper electrodes wear. Electrode Tip Dresser (ETD) can help you achieve better, more consistent welds, without a tiring and labor-intensive routine.

2. Features

1) Correspond to majority of cap tip shapes

2) Cutter holder fit into various types of tip dresser from each maker

3) Contribute to reduce the cutter variety and inventory management

4) Support the long life span of cutter blade and reduce dressing time

3. More pictures

|