4.Production Equipments

At present, the company’s factory area exceeds 3000 square meters,

and an additional 3000 square meters are under planning and design,

covering the complete production process of material research and

development, main component production, and testing. The company

has 6 technical person,over 40 workers, and multiple imported

production and testing equipment from Taiwan and Germany.

5. Why Choose Us

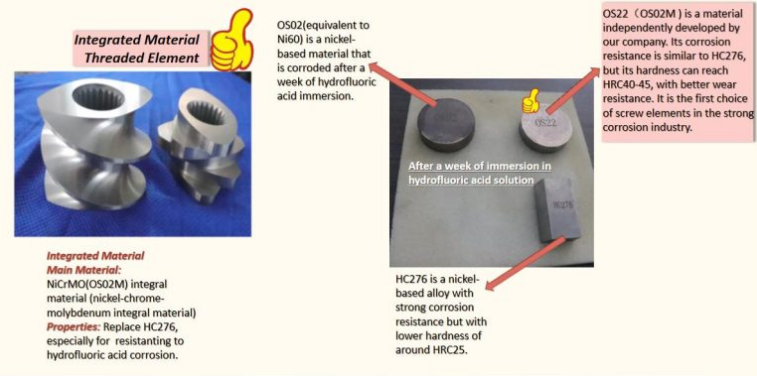

1) Independent research and development of materials and processes can ensure the performance and process of materials to the maximum extent, and greatly prolong the service life compared with ordinary products, while the main supplier in the market only buy raw materials for machining.

2) Continuously Research and improving the materials based on different application and different customer requirements. For example, for the screw elements used in hydrofluoric acid , we get our new materials of OS02M, its corrosion resistance is similar to HC276, but its hardness can reach to HRC40-45. so this materials both has good corrosion resistance and high wear resistance. It is the first choice Materials of screw elements used in strong corrossion industry.